Stainless Steel

|

Material |

Stainless Steel |

|

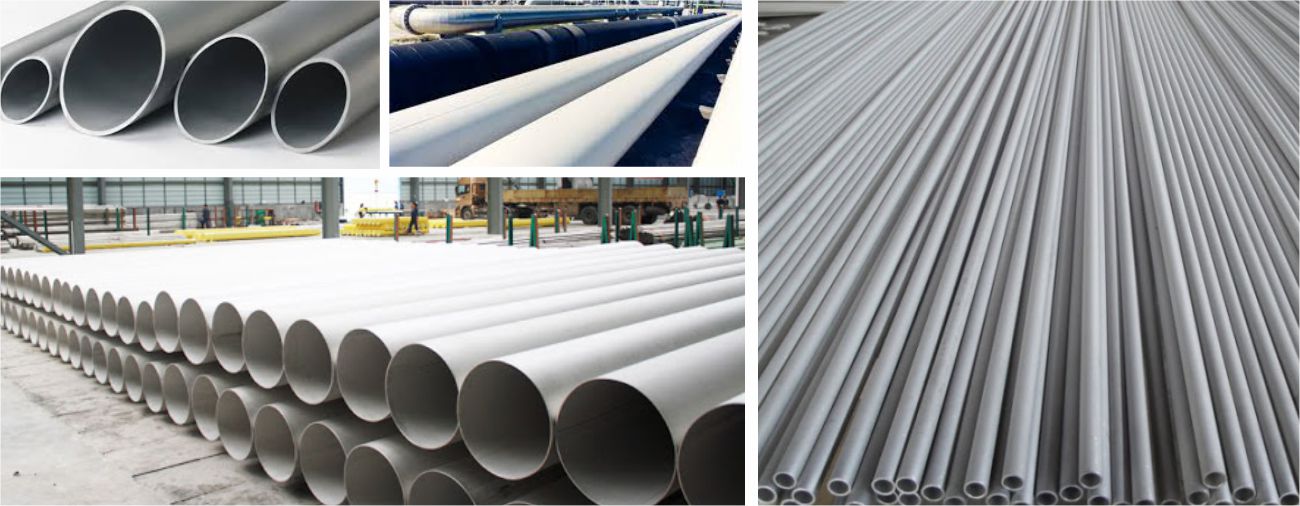

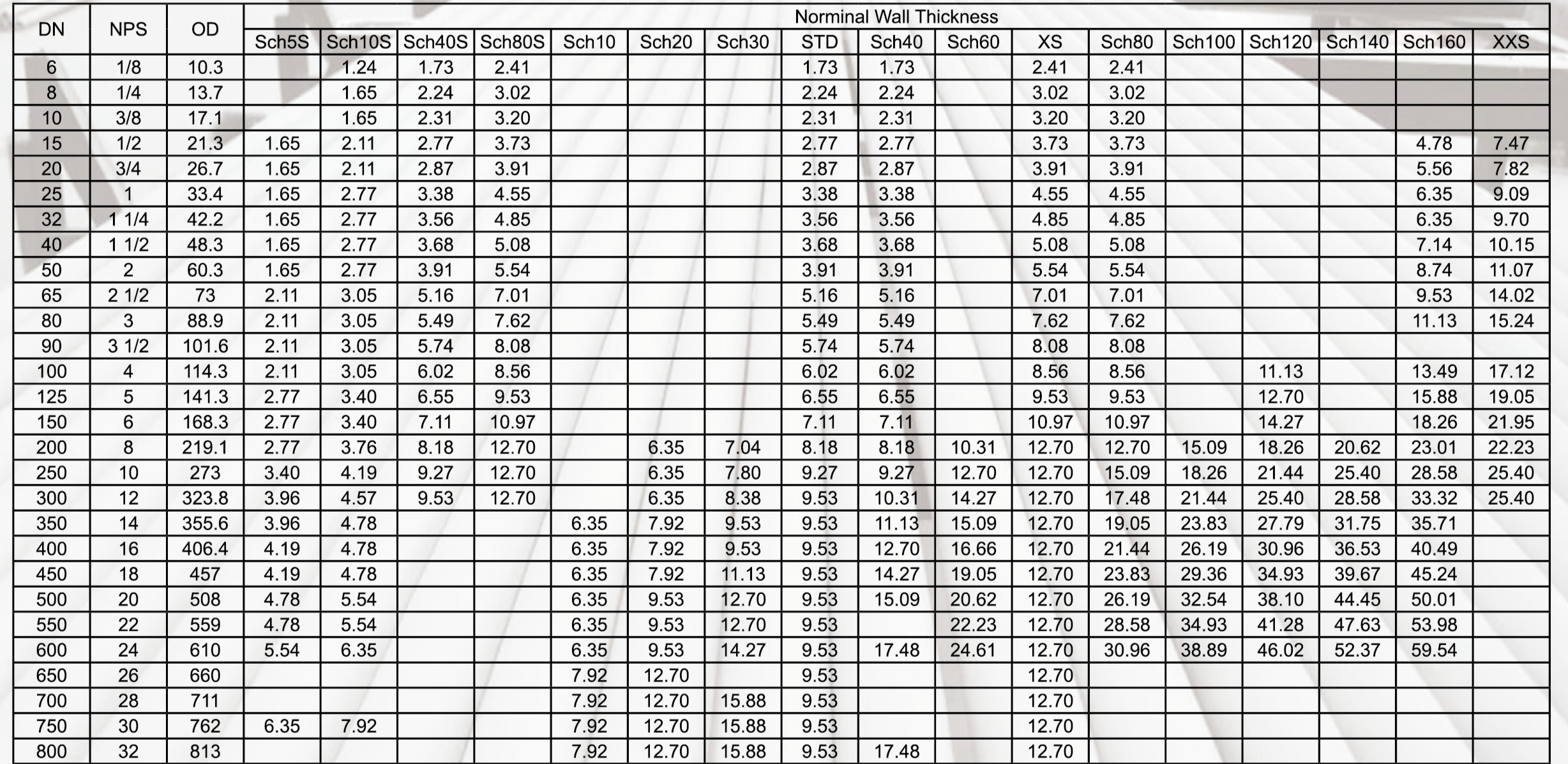

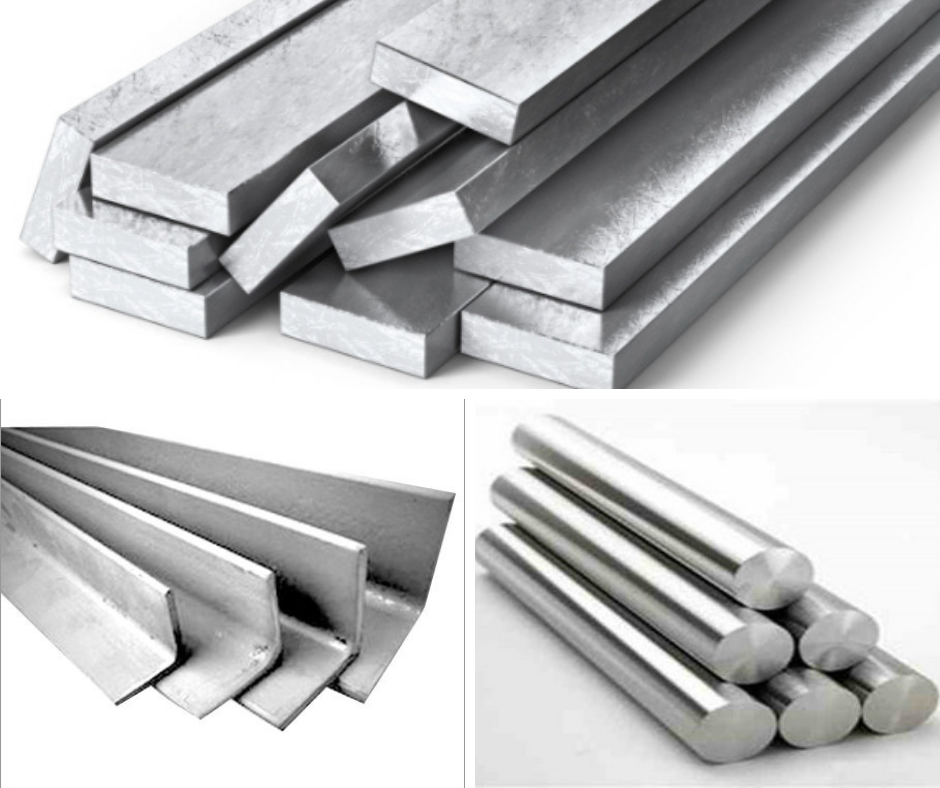

Type |

Coil, Plate, Bar, Seamless/Welded Pipe, Strip, Circle |

|

Surface Finish |

No.1, 2B, 4B, BA, HL, 8K, Mirror etc |

|

Grade |

201, 202, 304, 304L, 316L, 316Ti, 317, 309, 310, 321, 430, 409, 410, 410S, 420 etc |

|

Standard |

ASTM, AISI, JIS, DIN, EN, GB |

|

Thickness |

0.2mm - 80mm |

|

Length |

1000mm - 8000mm |

|

Width |

1000mm - 2000mm |

|

Packing |

Standard export sea-worthy packing, Bundles, seaworthy wooden cases.With edge protector, steel seals or as per customers' requirement |

We also provide surface treatment for both Hot and Cold rolled stainless including COLD/HOT

- Mirrored/Polishing

- Plated Wire Drawing

- Etched

- Embossed

- Inked

- Lasered

- Scractched

- Anti-skid

- Anti-fingerprinting treatment

- Wire Drawing

Application

- Petrochemical Industry

- Construction

- Chemistry Industry

- Heat & Power plant

- Machine

- Building

- Architectural decoration industry

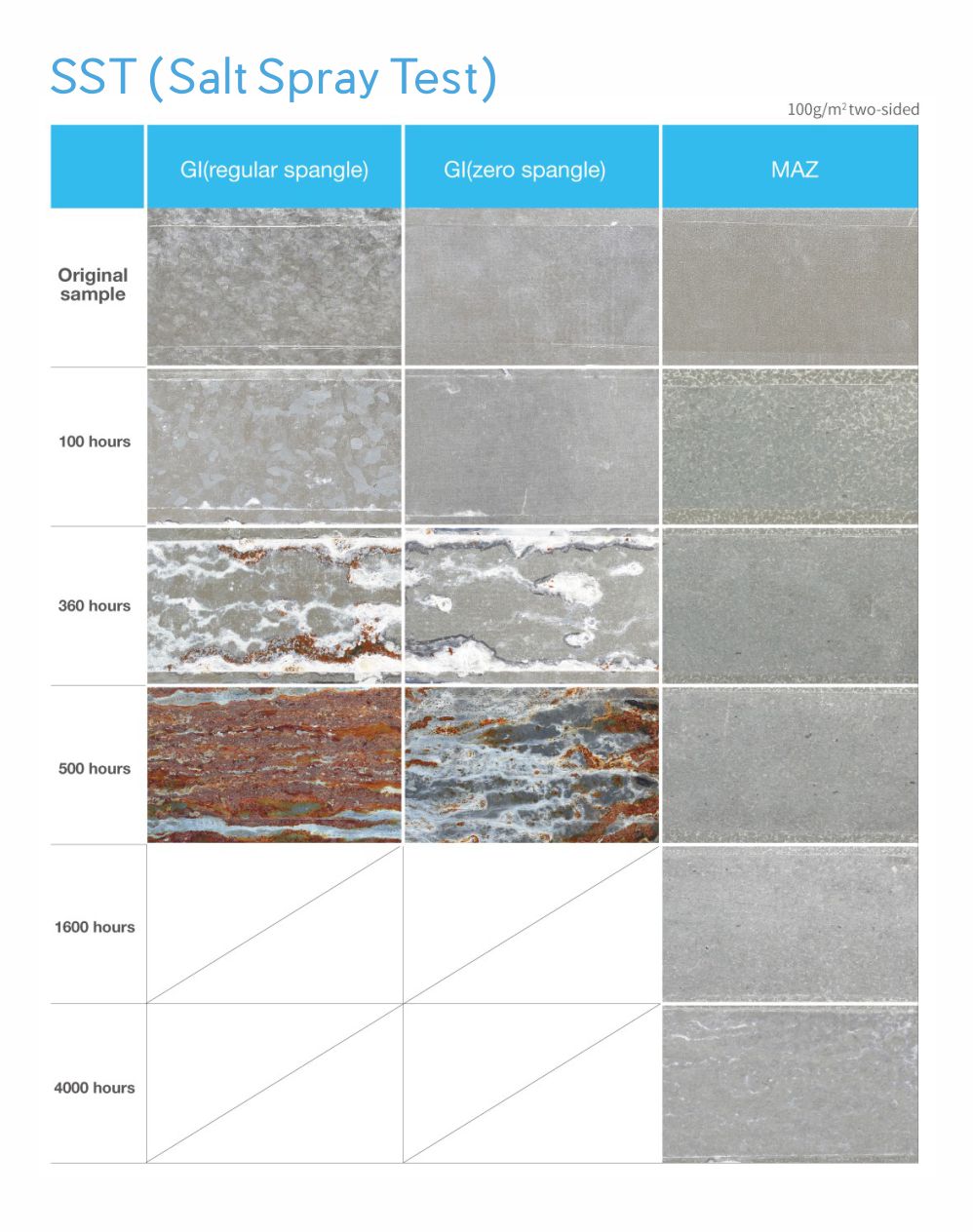

y conducted Salt Spray Test (SST) on 100g of MAZ coated plate and 100g of galvanized plate at the same period, It was found that MAZ do not rust after 4000 hours on Salt Spray Test (SST).

y conducted Salt Spray Test (SST) on 100g of MAZ coated plate and 100g of galvanized plate at the same period, It was found that MAZ do not rust after 4000 hours on Salt Spray Test (SST).